Case Study

IC Process To Save Time And Money – Machine Locators

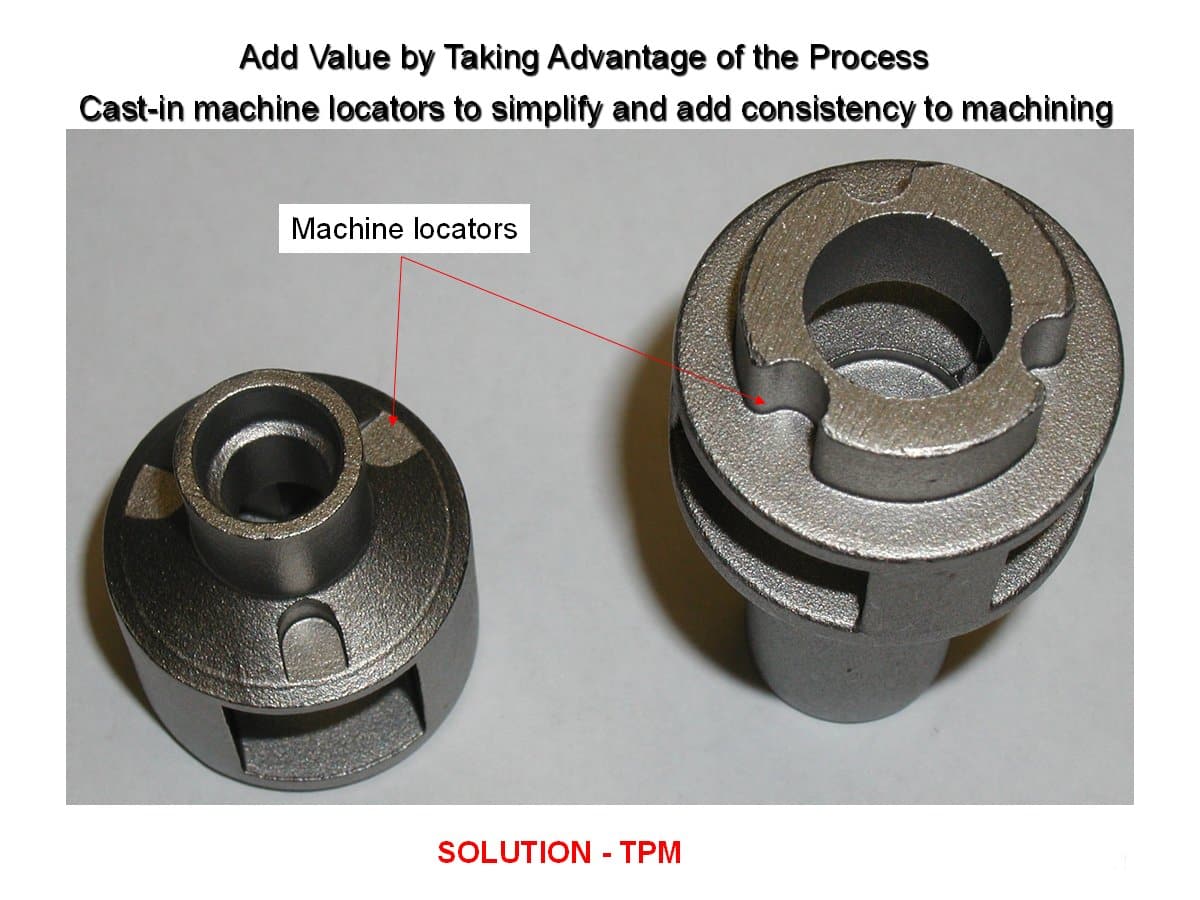

- Notes: Cast Machine Locators to reduce setup times

TPM always wants to better understand how a part is used – form, fit, function, etc. In this way we can work with our customer to best use the advantages of the Investment Casting Process to add the most value to a part.

An example is to cast in features used to more precisely hold and locate the part for machine setup. By understanding how the part is used TPM can suggest ideas on how to make any machining required faster and easier.

Other reasons to cast in locators would be for a welding fixture, paint fixture or assembly fixture. Often a feature can be cast into the part without affecting functionality that will locate the part in a fixture in the same manner each time.

Even if the parts are cast near net size subsequent setups can be reduced or simplified.

TPM is able to cast slots, pockets and several other shapes into parts to create a consistent/repeatable fixturing point. The photo shows some typical examples.

The end result is that TPM is able to provide parts to our customer with cast features that recue machine or fixture set up time.

Connect With Us

Maximize The Value Of Your Investment

To request additional information please feel free to contact us by any of the options provided.

Our office hours are Monday through Friday 8 a.m. – 5 p.m. central. We will be happy to talk with you.