Investment Casting

Discover The Advantages

We produce customized investment cast parts for a wide variety of demanding applications — such as those listed below.

- Investment castings allow complex part geometries, including using one casting to replace several pieces in an assembly

- Fine features are possible

- You get parts at net or near-net shape, so little machining is needed

- You can specify a wide range of ferrous and non-ferrous alloys

- It isn’t necessary to do long production runs

Click here to download the Investment Casting Manufacturer's Guide

"*" indicates required fields

The Process of Investment Casting

After your part is defined and planned, and we’ve walked through your needs for documentation and doing business, there are five major steps to get your investment cast part prototyped and into production.

Wax Pattern

Creating a wax pattern is just the first step toward getting your parts into production. Wax patterns are created using a customer owned die or tool into which warm wax is injected to create a pattern that is very much like the desired end part. Alternatively, a 3D printed pattern can be used in place of the wax pattern. TPM can review these options so the best method is utilized for each product.

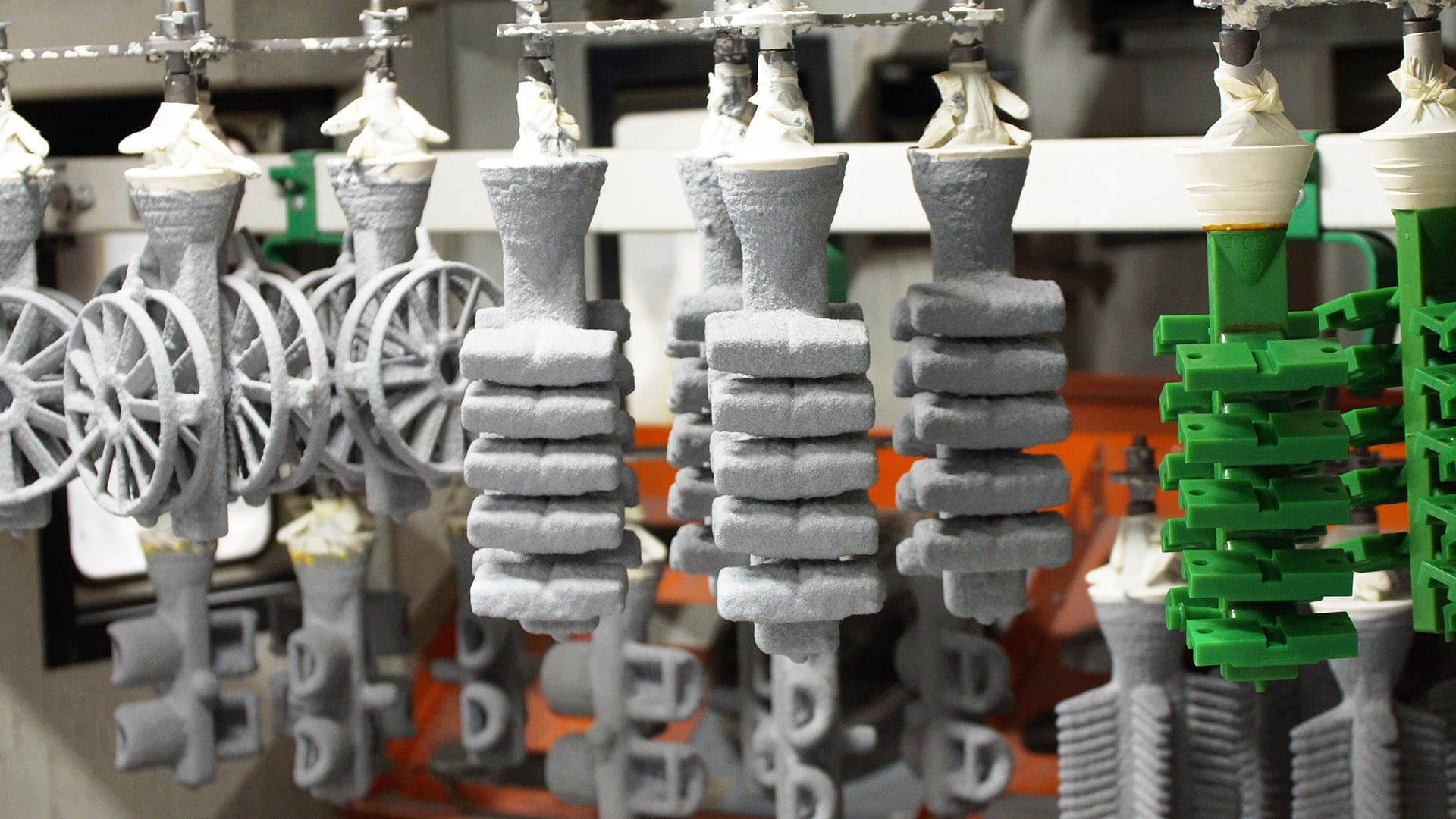

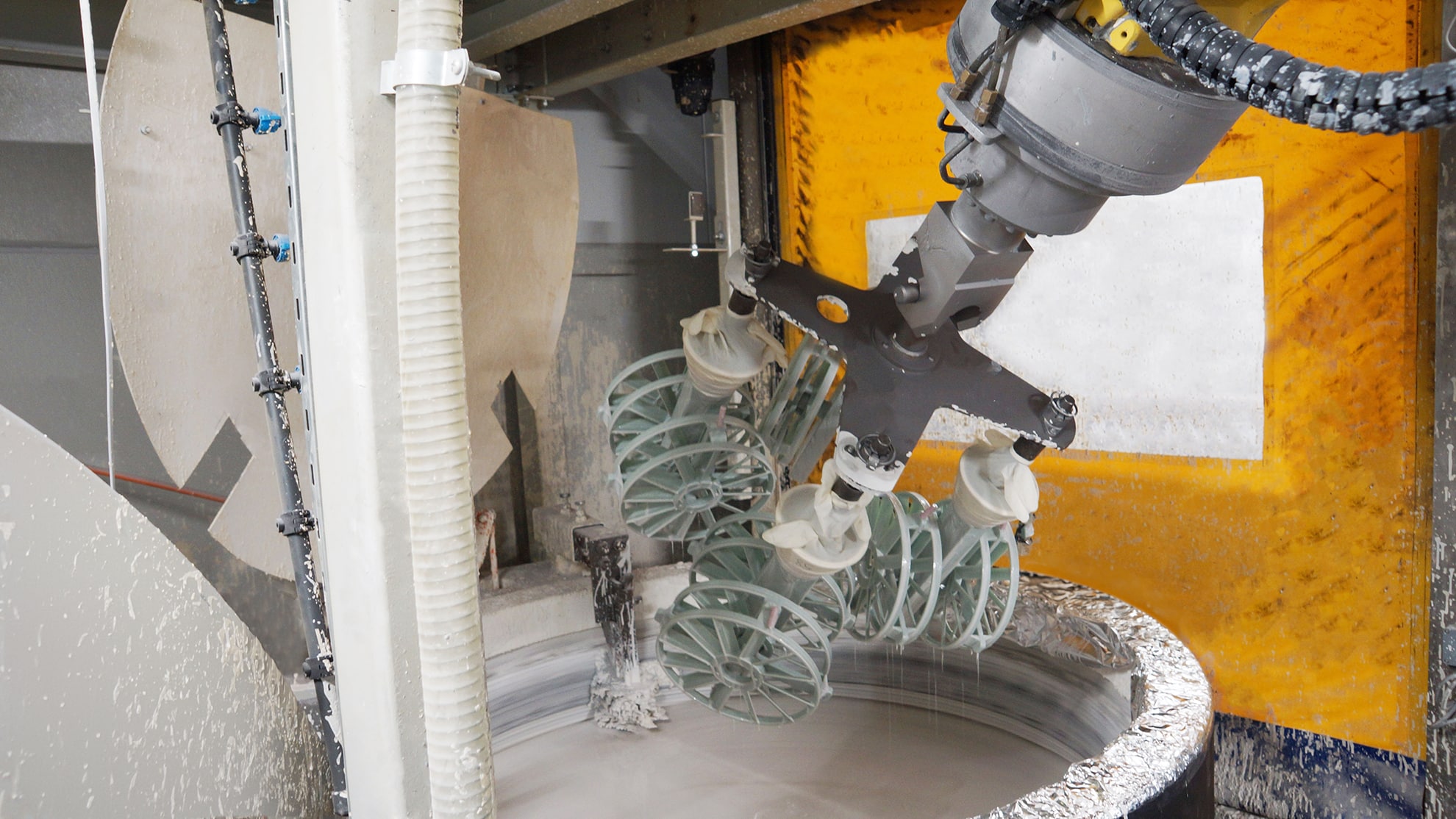

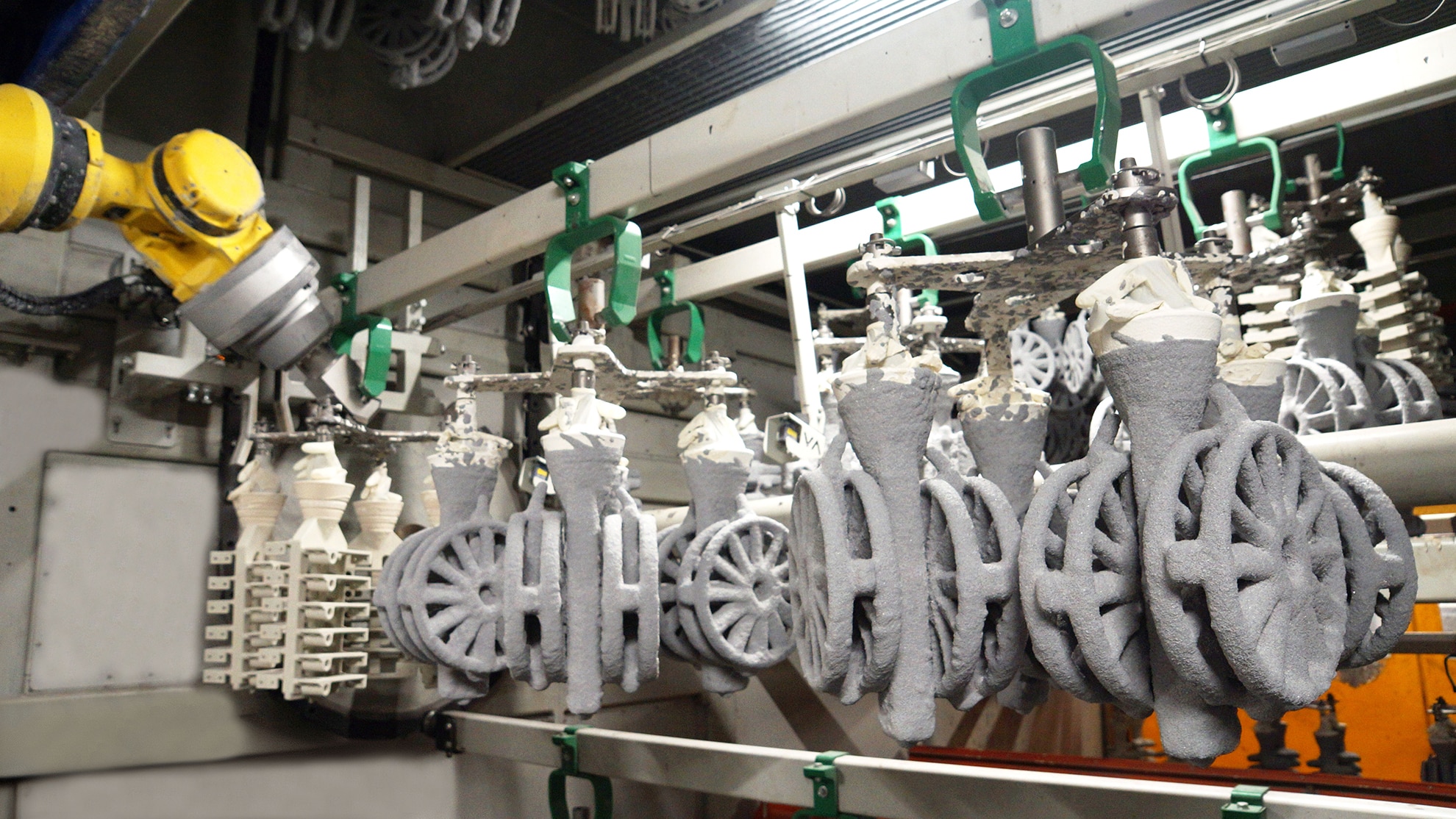

Ceramic Shell

After the wax pattern is made and attached to a running system or tree, a highly engineered ceramic shell is created in multiple layers to form the mold that will eventually hold the molten metal that forms the desired parts. TPM primarily used a sophisticated robotic system to apply the ceramic shells. Once the proper number of layers is complete and the shell is thoroughly dried the tree is ready for wax removal.

Pouring

Prior to pouring the molten metal into the ceramic shell the wax must be removed and the hollow shell must be fired or pre-heated. TPM utilizes the latest technology in flashfire dewax to remove the wax from the shelled tree. This process is also commonly referred to as lost wax. TPM’s flashfire equipment allows us to capture almost all of the wax so it can be recycled.

Once the wax is removed, the empty shell is heated to a 1800 degrees Fahrenheit when the shell goes through a phase transformation making it strong enough to withstand the 3000 degree Fahrenheit molten metal that is poured into the shell.

After the metal has cooled and solidified, it will be ready for the next step of the operation.

Rough and Final Clean

The ceramic shell is removed and metal parts are cut from the tree, typically by abrasive cutoff sews. Parts are blasted to remove any residual shell and the gates are removed resulting in a nearly complete metal part.

Inspection and Post Process

The parts are then inspected to confirm they meet both the standards for an acceptable casting and per customer specifications. Parts are then prepped for any post process operations that are required. For example, heat treatment, machining, MDT, coating, or other.

At this point parts are carefully packed and shipped to our customer.

Optimize Your Process

With our advanced technology and expertise, we streamline the casting process to ensure efficiency and precision.

Consistent

Reduce production costs without compromising quality or performance by minimizing raw materials and mitigating the need for surface finishing.

Reliable

We deliver high quality parts on a 4-6 week turnaround.

Comprehensive Investment Casting Services

At TPM, we prioritize quality and timely delivery in our investment casting services. With our global production capabilities, we ensure that our customers receive their parts on time, every time.

Design Assistance

Our experienced engineers provide expert design assistance to optimize your cast parts for performance and efficiency.

Prototyping Services

With our prototyping services, you can quickly validate your designs and make necessary adjustments before moving to full-scale production.

Full-scale Production

We have the capabilities to handle large-scale production runs, delivering high-quality cast parts on time and within budget.

Connect With Us

Maximize The Value Of Your Investment

To request additional information please feel free to contact us by any of the options provided.

Our office hours are Monday through Friday 8 a.m. – 5 p.m. central. We will be happy to talk with you.