Knowledge Center

Discover the Latest Insights

Click here to download the Investment Casting Manufacturer's Guide

"*" indicates required fields

Frequently Asked Questions

What is investment casting?

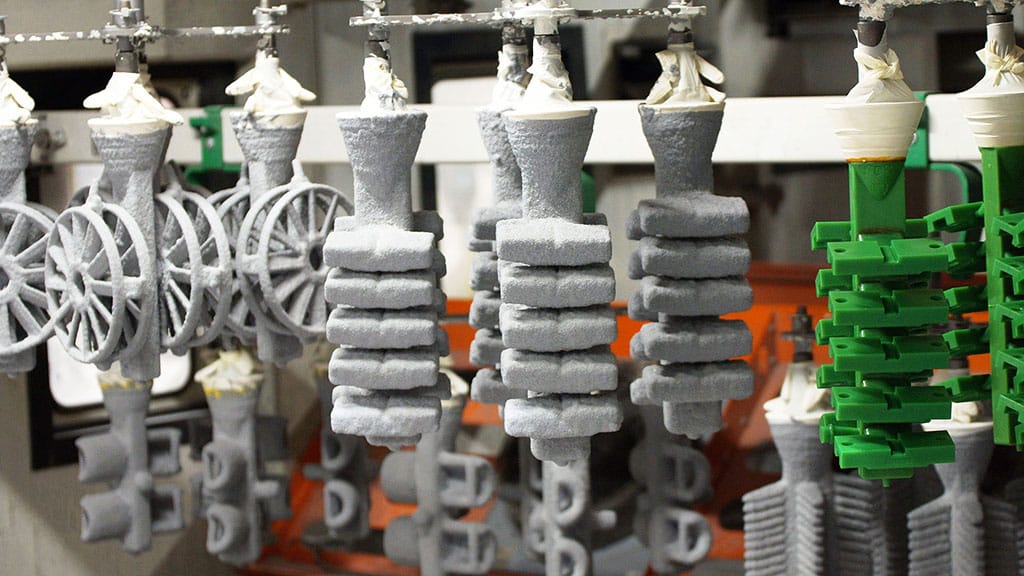

Investment casting, also known as lost wax casting, is a manufacturing process where a wax pattern is used to shape a ceramic mold. Once the mold is formed, the wax is melted away and molten metal is poured into the mold to create the part.

What materials can Texas Precision Metalcraft work with?

Texas Precision Metalcraft works with a variety of metals including aluminum, carbon steel, stainless steel, nickel, cobalt, and copper-based alloys.

What industries does Texas Precision Metalcraft serve?

Texas Precision Metalcraft serves a wide range of industries, including oil and gas, manufacturing, food processing, and more, providing custom-engineered solutions to meet specific needs.

Can Texas Precision Metalcraft handle secondary operations?

Yes, we provide turnkey parts, including secondary operations such as painting, to deliver ready-to-use components.

Where are Texas Precision Metalcraft’s manufacturing facilities located?

Their primary facility is in Sugar Land, Texas, but we also have plant operations internationally to offer a mix of speed and cost efficiency.

What is the typical size of parts produced by Texas Precision Metalcraft?

The parts produced in Sugar Land are typically below the size of a basketball. Larger parts are manufactured in our offshore facilities.

Does Texas Precision Metalcraft offer onshoring options?

Yes, for customers needing Made in USA products and the shortest lead times, our Sugar Land facility is ready to respond. We also offer offshore production options to balance cost and production schedules.

How does Texas Precision Metalcraft ensure part quality?

We build quality into their parts from the initial tool design to final product inspection, ensuring that parts meet exact specifications and tolerances required by customers.

What is the lead time for orders?

Texas Precision Metalcraft prides itself on offering the shortest lead times by leveraging both their local and offshore facilities depending on customer needs. Our lead times are usually 6 to 8 weeks, which can be two to three times faster than the industry’s typical lead times.

Can Texas Precision Metalcraft help with design requirements?

Yes, our team of engineers, sales, and customer service professionals will work with you from the initial design to the delivery of parts, ensuring that your design requirements are met.

How can I contact Texas Precision Metalcraft for more information?

Contact us via phone at (281) 240-9191, fax at (281) 240-2472, or email at sales@txpm.com or info@txpm.com. Our office hours are Monday through Friday from 8 a.m. to 5 p.m. Central Time.

What types of casting processes does Texas Precision Metalcraft offer?

In addition to investment casting, Texas Precision Metalcraft offers various casting solutions tailored to the specific needs of our clients, ensuring the best process is used for each part.

Can Texas Precision Metalcraft assist with prototyping?

What is the typical production capacity of Texas Precision Metalcraft?

Texas Precision Metalcraft can handle both small and large production runs, with the flexibility to scale up production as needed to meet customer demands.

How does Texas Precision Metalcraft handle quality control?

Quality control is integral to our process, with thorough testing and inspection at every stage of production to ensure all parts meet stringent quality standards.

Are there any design limitations for investment casting?

What are the benefits of using investment casting for manufacturing parts?

Investment casting provides high precision and excellent surface finish, allowing for complex geometries and reducing the need for additional machining, which can save time and costs.

Does Texas Precision Metalcraft offer expedited services?

Yes, Texas Precision Metalcraft offers expedited services to meet urgent production deadlines, utilizing our streamlined processes and efficient workflows.

How does Texas Precision Metalcraft support lean production operations?

Texas Precision Metalcraft supports Lean production by ensuring timely delivery, minimizing waste, and continuously improving their processes to provide the most efficient and cost-effective solutions for our customers.

Connect With Us

Maximize The Value Of Your Investment

To request additional information please feel free to contact us by any of the options provided.

Our office hours are Monday through Friday 8 a.m. – 5 p.m. central. We will be happy to talk with you.