Understanding the Investment Casting Process

Investment casting is a precise, repeatable way to turn complex designs into high quality metal parts. If you are new to metal casting, this guide breaks the workflow into plain English steps and explains what to expect from a partner.

What is investment casting?

Investment casting, sometimes called lost wax casting, uses a disposable pattern to create a ceramic mold. The mold receives molten metal, solidifies, and yields a near net shape part with smooth surfaces and predictable dimensions. It is a versatile metal casting process.

Step 1: Pattern creation

A wax pattern is formed in a tool or die that matches your part geometry. For speed or early iterations, a 3D printed pattern can replace wax, letting engineers test designs. Patterns are assembled on a “tree” so multiple parts can be poured in one cycle.

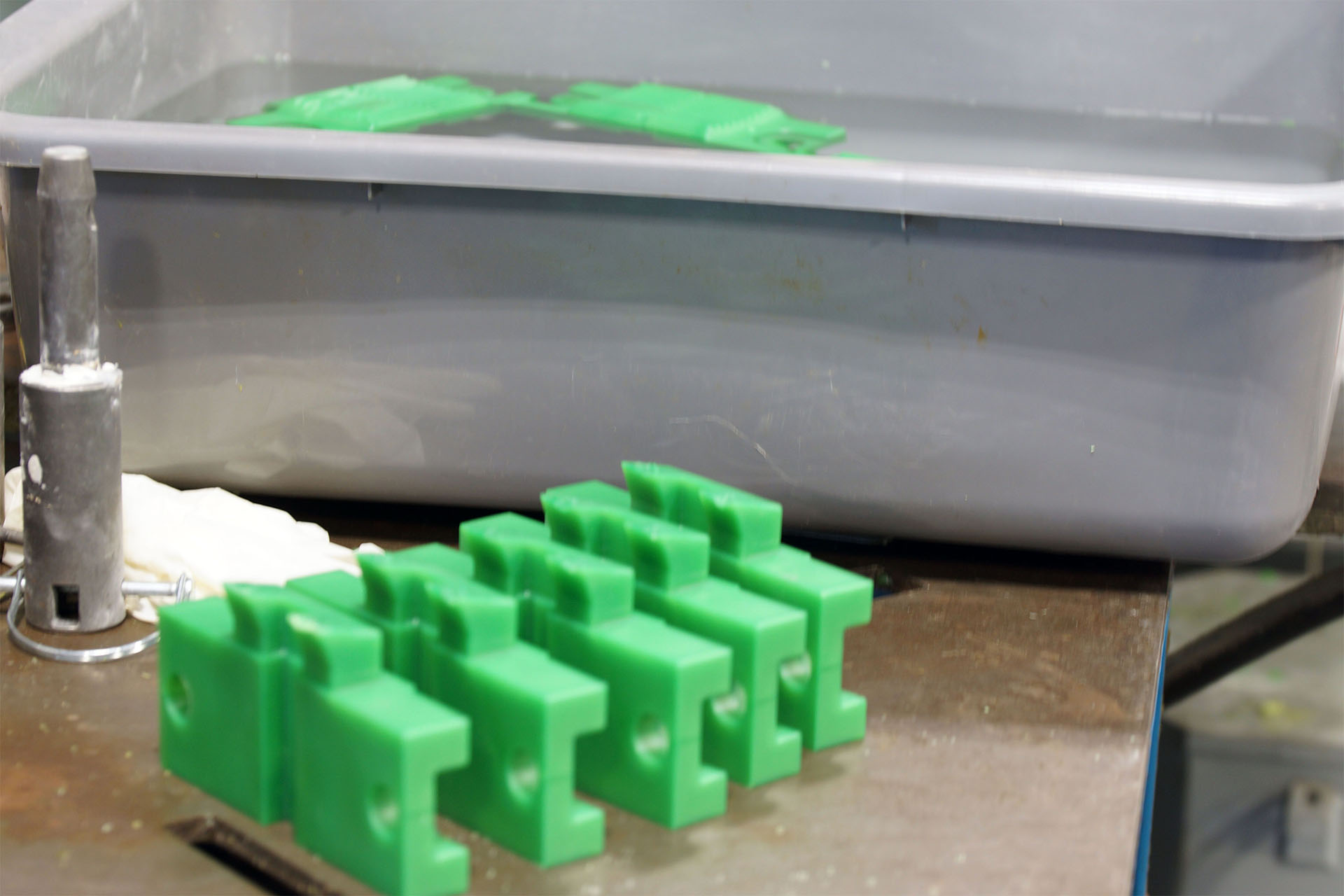

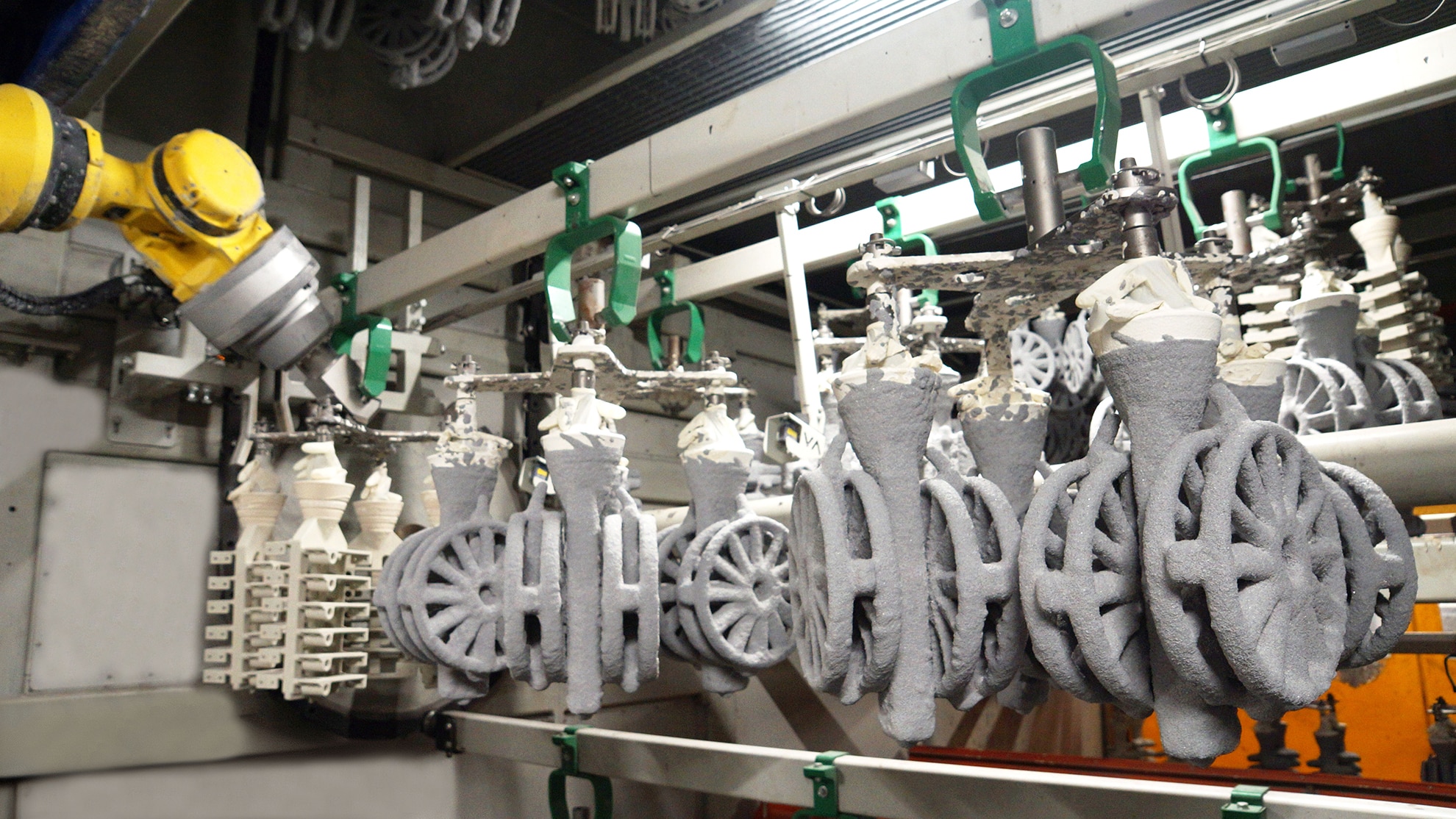

Step 2: Build the ceramic shell

The pattern tree is repeatedly dipped and coated to build a strong ceramic shell. After the required layers cure, the shell becomes the mold that will receive metal during pour.

Step 3: Dewax, preheat, and pour

The wax is removed from the cured shell using a high energy dewax process. The empty shell is then fired to reach casting temperature. Molten alloy is poured into the cavity and allowed to cool and solidify before the next step.

Step 4: Knockout and clean

Once solid, the ceramic shell is broken away to reveal the casting tree. Individual parts are separated from runners and gates, then blasted to remove residual shell. The result is a clean, near net shape part ready for finishing.

Step 5: Inspect and finish

Castings are inspected against drawing requirements and applicable standards. Depending on the application, secondary processes may include heat treatment, machining, surface finishing, coating, and additional testing. Finished parts are packaged and shipped.

How it compares to other metal casting methods

- Sand casting: great for large, robust shapes and cost sensitive programs, with more machining.

- Lost foam: enables intricate internal passages and consolidation of features.

- Centrifugal casting: excels on rings and tubes that demand dense, uniform walls.

Investment casting stands out when thin walls, crisp detail, and repeatability are priorities.

Typical applications and alloys

Common investment casting applications include impellers, brackets, housings, valve bodies, and precision pump components. Typical alloys range from stainless and carbon steels to aluminum and nickel based options. Your use case, environment, and tolerance targets guide the best combination of process and material.

Why teams choose investment casting

Compared with other metal casting methods, investment casting excels when you need thin walls, fine detail, excellent surface finish, and reliable repeatability. Because parts come off the tree close to final shape, you spend less on machining and material, and you protect critical sealing and cosmetic surfaces.

What to expect from a good partner

Look for clear manufacturability feedback, flexible pattern options, and documented quality at each checkpoint. Ask how prototypes will be delivered, how dimensional reports are shared, and how the process scales to production. A partner that treats communication as part of the process helps you maintain schedule discipline while protecting engineering intent.

Understanding the steps makes supplier conversations easier. If you want a deeper look at benefits and design guidance, explore our investment casting overview. If you are ready to validate a part in real metal, send your CAD file for a quick feasibility check. When timing matters, request a fast, no nonsense quote and we will return a clear plan to move your program forward today.