Austin TX Rapid Prototyping

In Austin, hardware innovation moves at startup speed. Ideas evolve quickly, timelines are compressed, and there’s no room for prototyping bottlenecks that kill momentum. That’s why Austin’s most ambitious builders choose Texas Precision Metalcraft for rapid prototyping that keeps pace with their vision.

We understand the Austin ecosystem. Hardware startups need to prove concepts quickly. Established companies need to iterate faster than the competition. Engineering teams need test parts that perform like production components—not plastic approximations.

TPM bridges the gap between digital design and physical testing with rapid prototyping services tailored for Austin’s fast-moving innovation culture. Skip the tooling delays. Shrink your development timeline. Get real metal parts in just two weeks.

Here’s how we accelerate Austin innovation:

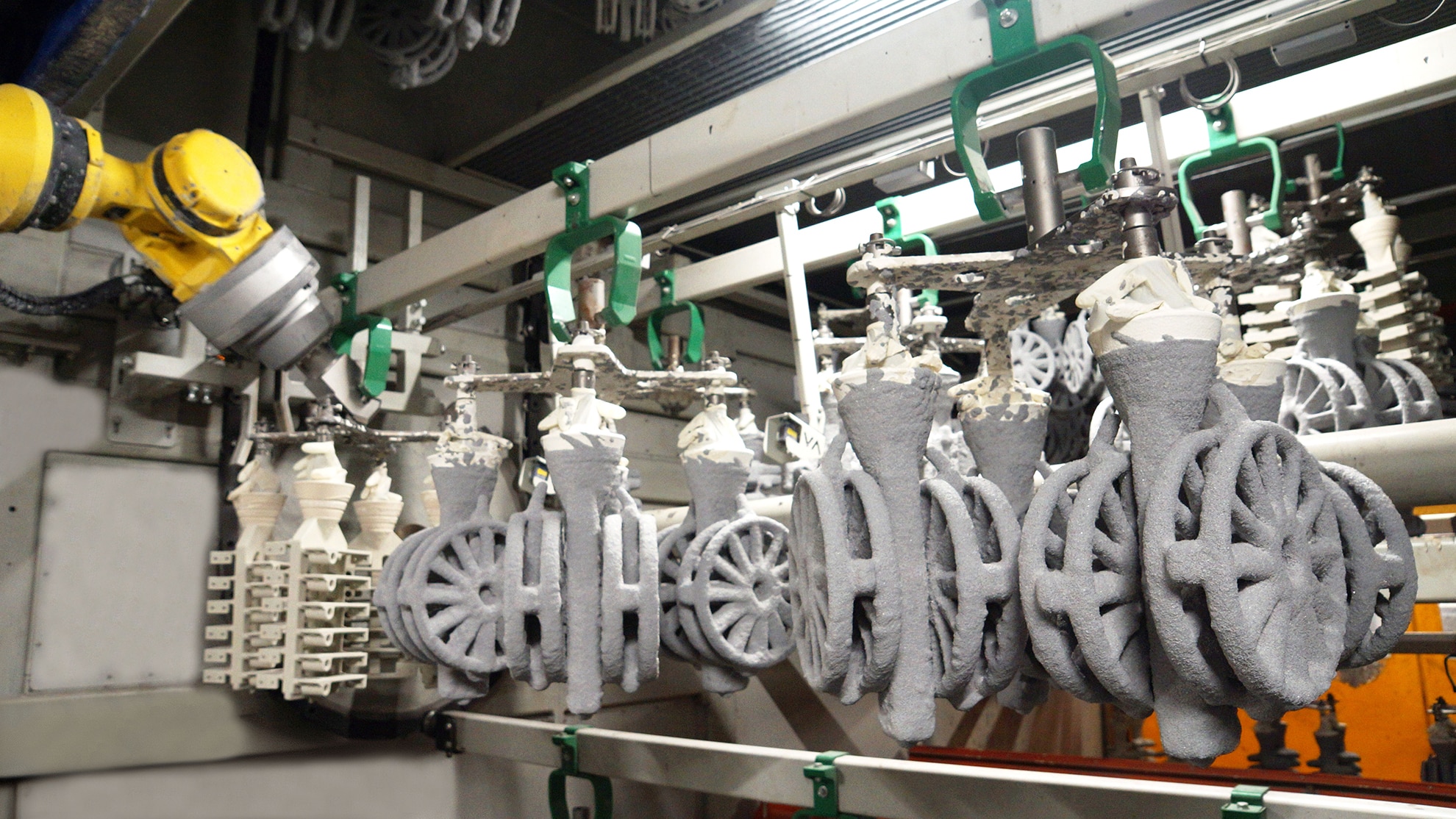

- Zero-Tooling Approach: Traditional prototyping requires expensive tooling and extended lead times. We use 3D-printed patterns to eliminate both barriers completely.

- Fast Design Validation: Test your concepts with actual cast metal parts, not substitutes. Understand real-world performance before committing to production.

- Scalable Process: Today’s prototype can seamlessly transition to tomorrow’s production run. No process changes, no quality compromises.

- Engineering Collaboration: Our team works with your engineers to optimize designs for both prototype testing and future manufacturability.

- Flexible Materials: Test with the same materials your production parts will use. Get accurate performance data from the start.

Austin’s hardware community doesn’t wait for perfect conditions—they create them. TPM provides the rapid prototyping capabilities that turn Austin concepts into testable reality. Whether you’re validating a breakthrough design or refining every detail, we deliver cast prototypes that perform.